Preparation:

1. Load the Test Transmission on the Test Bench and fix it on the Bench.

2. Connect Rear Axles of Test Transmission and Master Transmission with the help of Chains and Sprockets.

3. Adjust the Chain Tensions, with the help of idlers.

4. Fix the guard on chains, sprockets and on other drive components (like coupling shafts).

5. Fix the temperature sensors in the drain port of differential housing of Test Transmission as well as Master transmission.

Checks before Test:

1. Check Tightening of all nuts & bolts of couplings, sprockets, idlers, mountings, etc.

2. Check tensions of the chains, if not O.K. then adjust the same.

3. Check level of Transmission oil in both the Transmissions.

4. Check Coolant Level in the Radiator.

5. Check Fan Belt Tension of the Engine.

6. Check all Sensors for Proper working.

7. Check Throttle Control & Fuel Shut off mechanism for proper working.

8. Check Greasing on Support Bearing, Coupling Shaft and Chains.

9. Confirm proper positioning of Guards.

10. Check for any leakage.

Test Procedure:

1. Switch on the Control Panel of Test Bench.

2. Switch on the Water Pump of the Dynamometer and Adjust Water Pressure in between 1.6 ± 0.4 Kg/cm² by adjusting the Gate Valve.

3. Start the Engine of Test Bench at idle rpm and check working of all gauges of the Engine and Dynamometer.

4. Engage identical gear in both the Transmission (First in Master Transmission, then in Test Transmission) and adjust full throttle of the Engine by Throttle Control Lever.

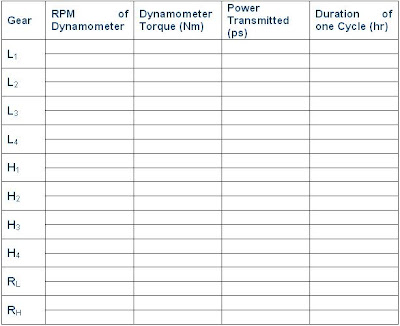

5. Load the Transmission in Different Gears, as per the following schedule -

6. In case of Emergency / Breakdown, immediately reduce the throttle to idle by throttle control lever, shut off the Engine by Fuel shut off mechanism and Unload the transmission.

7. Note down observation in the table given in Annexure - I.

8. After completion of 10 cycles in each gear (i.e. total 100 hrs.), compile the data as per Annexure - II.

9. Report Breakdown / Defects in the comments.

No comments:

Post a Comment